Monitoring seafaring ships from space, removing tumors without surgery and aluminium with super ductility — SPbPU engineers have been talking about what they do.

In 2020, following a competition organized by the Russian Ministry of Education and Science, a world-class scientific center called Advanced Digital Technologies was set up and the Peter the Great St. Petersburg Polytechnic University (SPbPU) was appointed as its coordinator. The center’s main goal is to ensure game-changing scientific and technological advances, based on world-class fundamental and applied research and to create the conditions for a transition to a fundamentally new level of application of high-tech know-how and high-efficiency modern digital production.

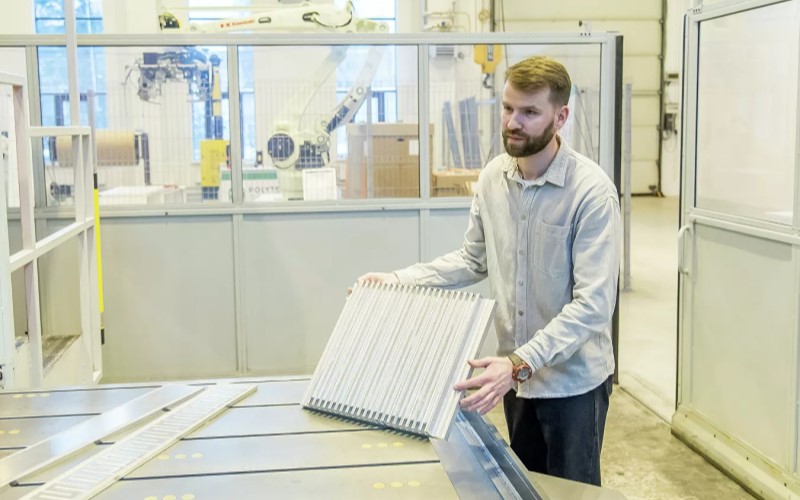

Aluminum with unique ductility

In the course of experimentation with the high-performance wire arc additive manufacturing (WAAM) of aluminium, researchers have come up with a metal possessing unique ductility. With the same chemical make-up as standard alloy, the plasticity of the WAAM version, and particularly its tensile strength before fracture, has gone up threefold from 12 to 41 percent. This means that three times more energy has to be used for it to fail and this kind of material will last longer in use.

“This discovery could fundamentally change notions of how components are manufactured,” explained Oleg Panchenko, head of the Laboratory of Lightweight Materials and Structures at SPbPU. “The mechanical properties of metal are always considered with a built-in margin, and in our case the margin exceeds established standards several times over.”

He said the most interesting application of this type of material is in the private aerospace sector, where the laboratory is working in partnership with S7 R&D Center.

“The manufactured material will make it possible to withstand deformations caused by load levels in space for longer,” according to Panchenko.

Read about other Polytech developments on the RUSSIA BEYOND website.